In 1994 DT Swiss launched the original Hügi ratchet rear hub, a marvel of Swiss precision engineering that set new standards for reliability and quality in the industry.

Today DT star ratchet remains a gold standard for rear hubs but time doesn't stand still and with 25 years of research, development and production experience behind them, it was time for DT Swiss's engineers to look again at the technology DT pioneered so many years ago.

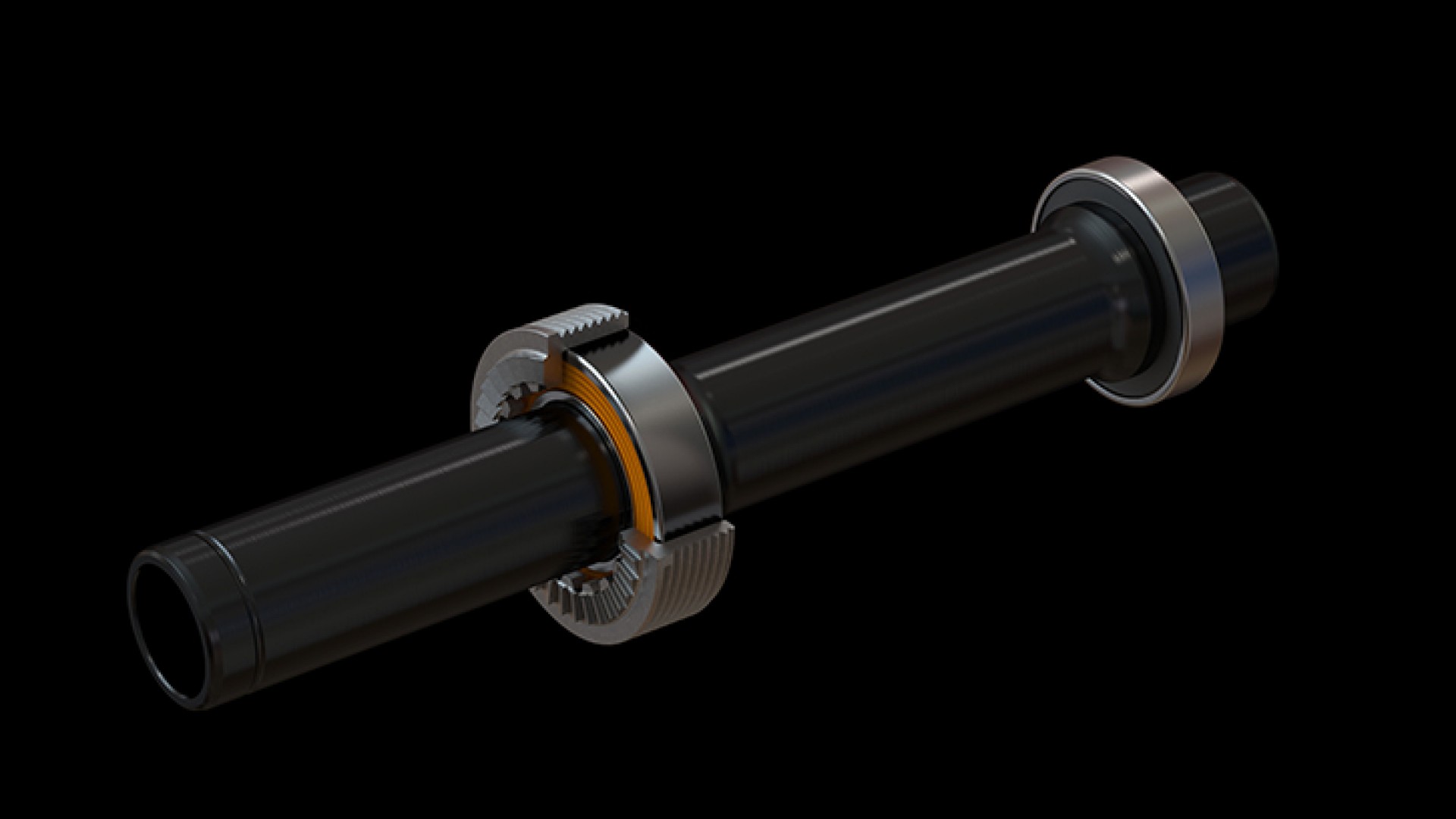

The result is Ratchet EXP, an even more refined and evolved ratchet system, by moving the drive side hub bearing inside the inner 36 tooth ratchet itself, DT have decreased the number of moving parts whilst giving the bearings a wider stance. A hub that is even more reliable and up to 20% lighter than the previous generation 180 and stiffer to boot with improved bearing alignment and long term durability, truly the finest racing hubs DT have ever made.

As with all top-end DT hubs, the 180's contain SiNC ceramic bearings, the very finest and smoothest competition bearings available and manufactured solely for DT to their specific design

The extensively machined hub shell, axle and end caps contribute to make these the lightest aftermarket hubs DT have ever made.

Simple maintenance

The no-tool concept allows the tool-free disassembly. Featuring an incorporated notch, the newly developed shape of the endcaps simplifies disassembly significantly and therefore makes the maintenance even easier.

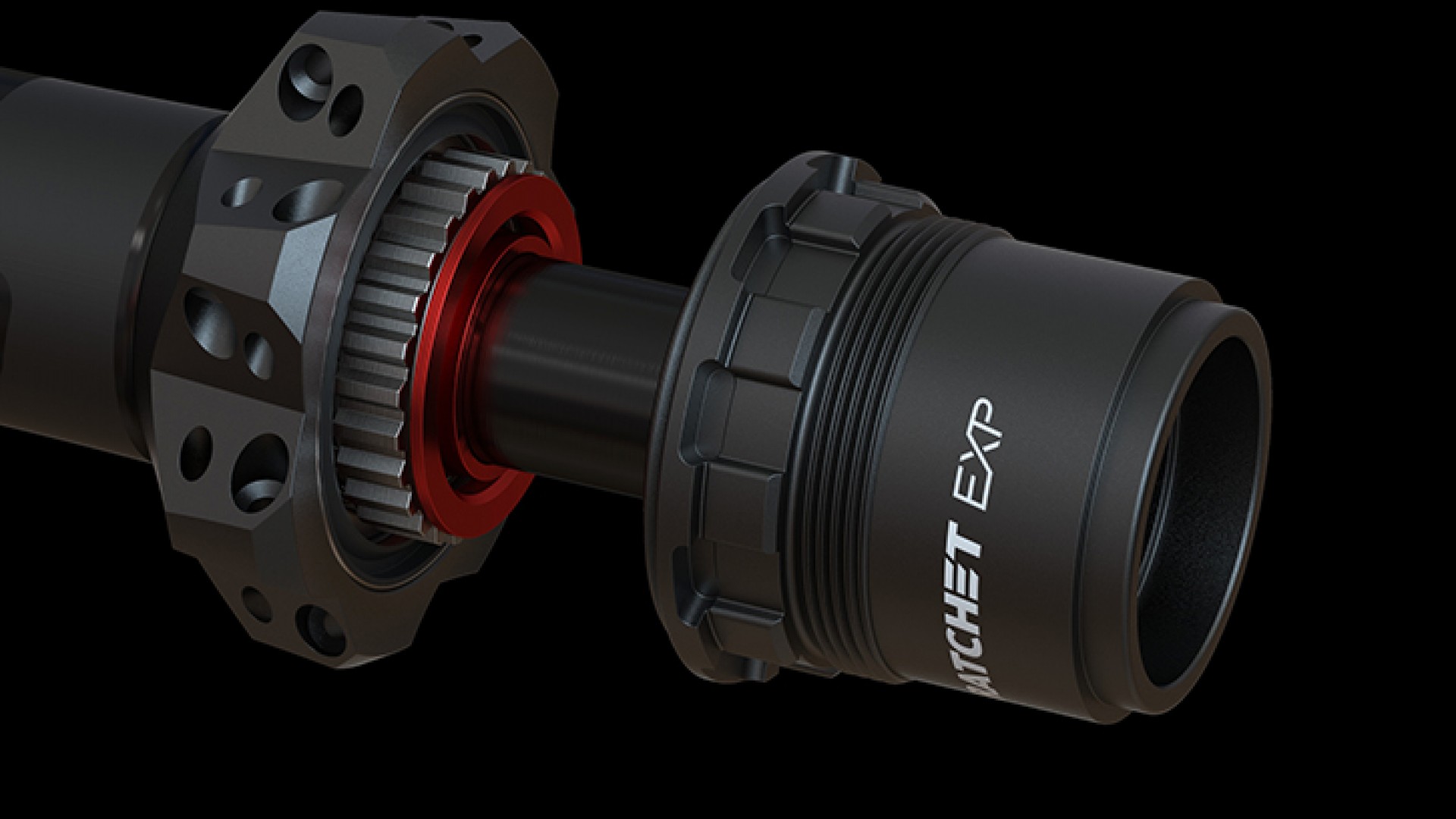

Freehub Body Conversion

The no-tool concept allows the conversion to a different drive train standard within seconds. All DT Swiss Ratchet System hubs can be converted.

Less weight

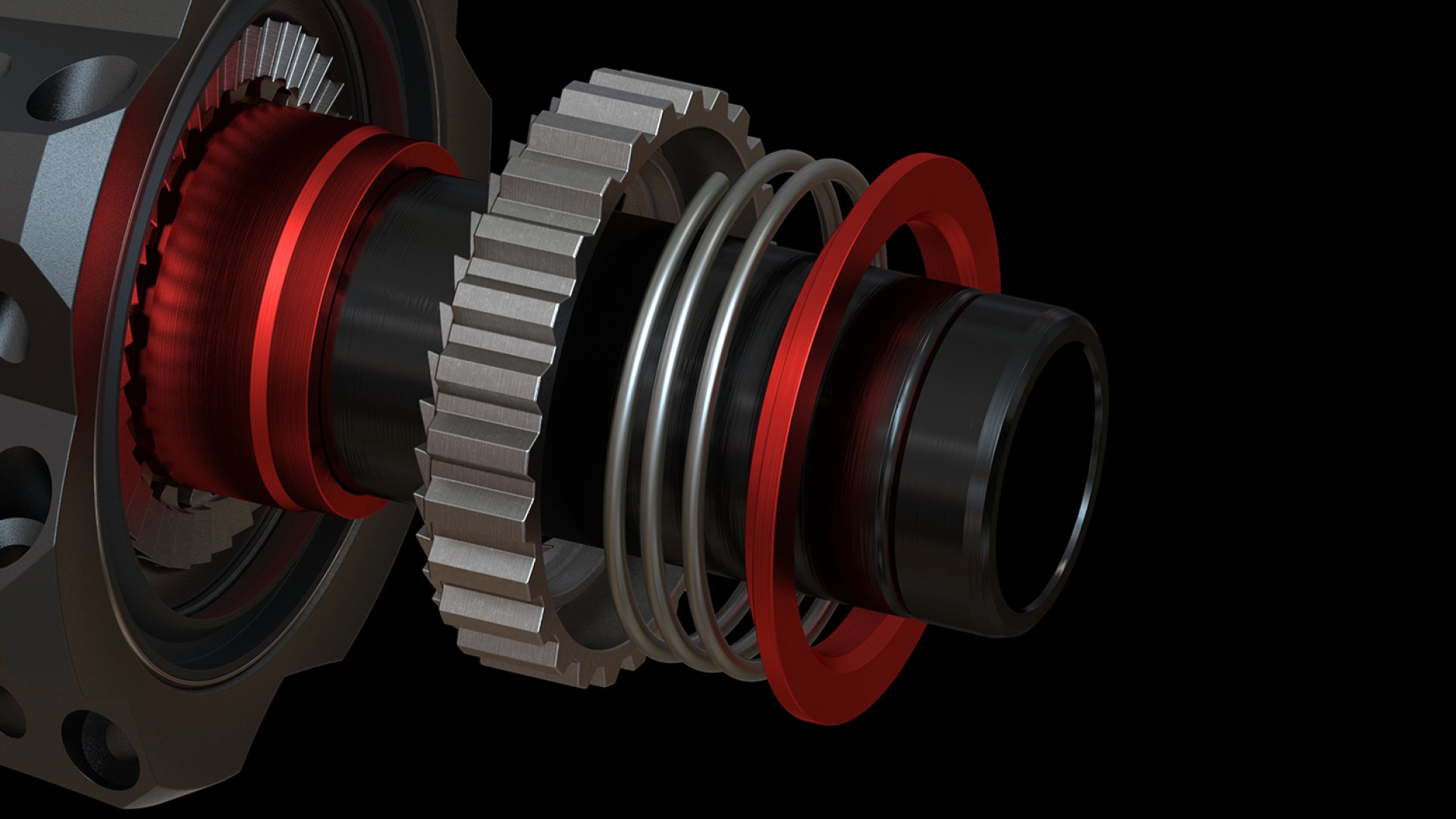

The previous Ratchet System required two springs to function correctly as the inboard ratchet was not fixed to the hubshell. The fusion of the ratchet and the threaded ring in the Ratchet EXP hub not only increase durability, it also reduces the overall number of components, utilizing a single spring, resulting in a decrease in weight of the freehub system.

More Precision

The previous systems required two conical springs which ensured the correct angle between the two ratchets. The fixed connection between the inner ratchet and the hub shell of the RATCHET EXP ensures that the inner ratchet is always aligned at the correct angle. Allowing the use of a single cylindrical spring resulting in a faster full engagement and therefore an increase in reliability.

Superior Reliability

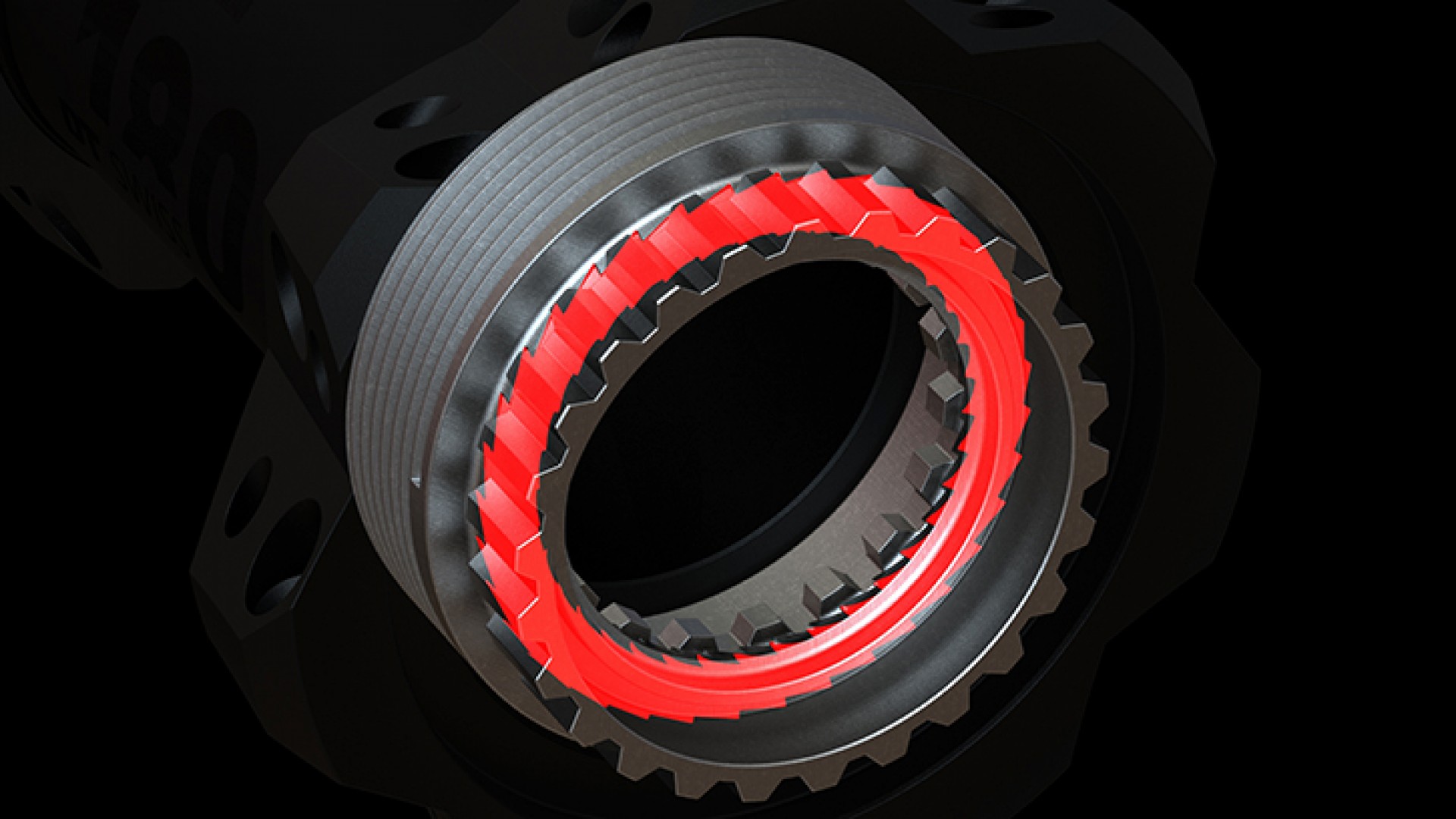

What makes the Ratchet System hubs superior is the fact that all teeth on each of the ratchets engage simultaneously every time. In the case of pawl hubs, the engagement surface area is rather small. With the Ratchet System, the whole front face engages, creating much smaller point loads. The result is the legendary reliability of the Ratchet System hubs

Increased Stiffness

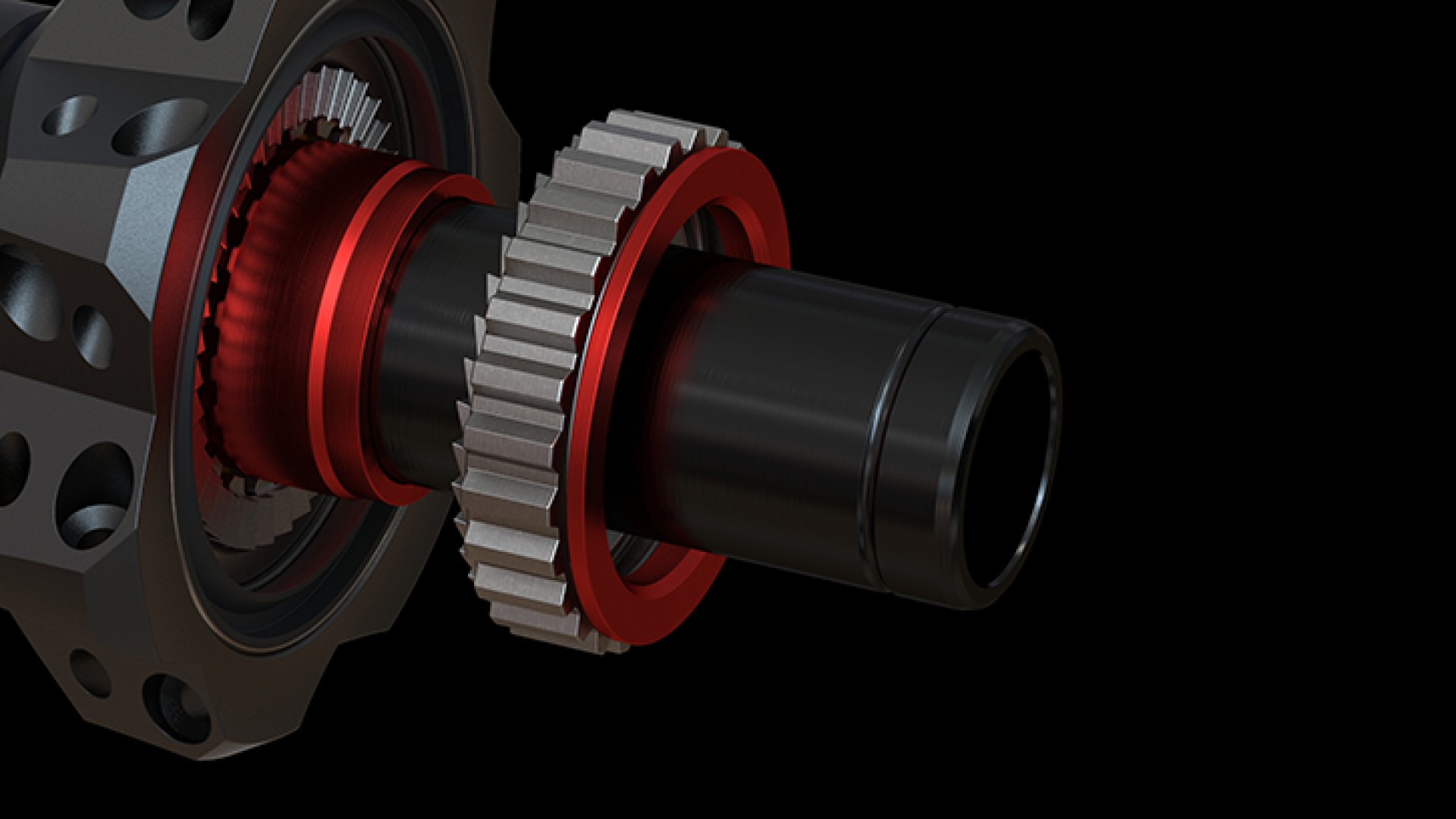

The hub stiffness is significantly defined by the distance of the bearings. For optimal performance it is important to maximize this distance, which is limited by the size of the freehub system. In the previous system the driveside bearing has to be placed next to the threaded ring and therefore the distance couldn’t be increased.

The integration of the drive side bearing into the threaded ring increases the bearing distance, resulting in a 15% improvement in hub stiffness.